For example, PE steel belt reinforced corrugated pipe is one of the plastic and steel composite pipes which is extensively used in water drainage and other applications.

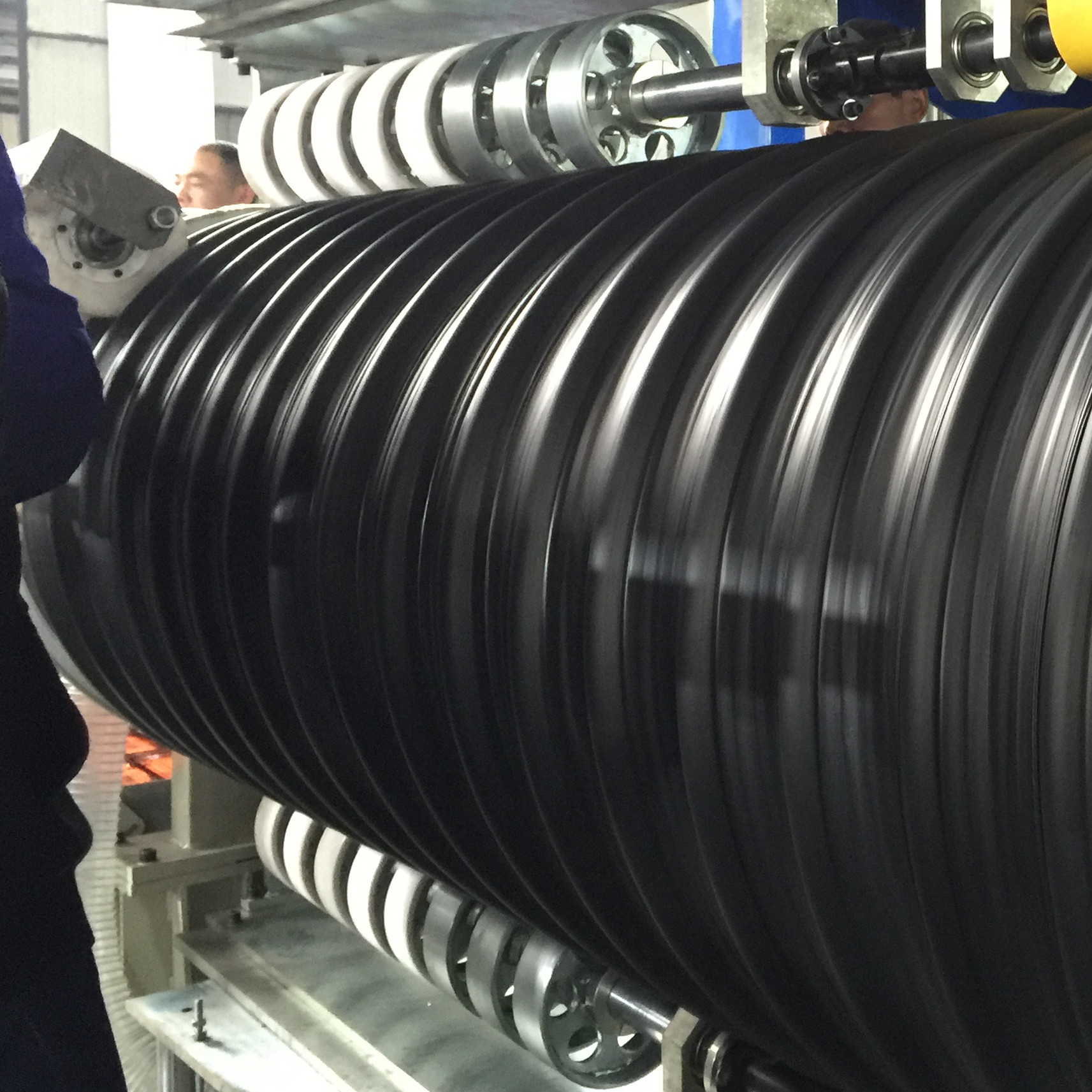

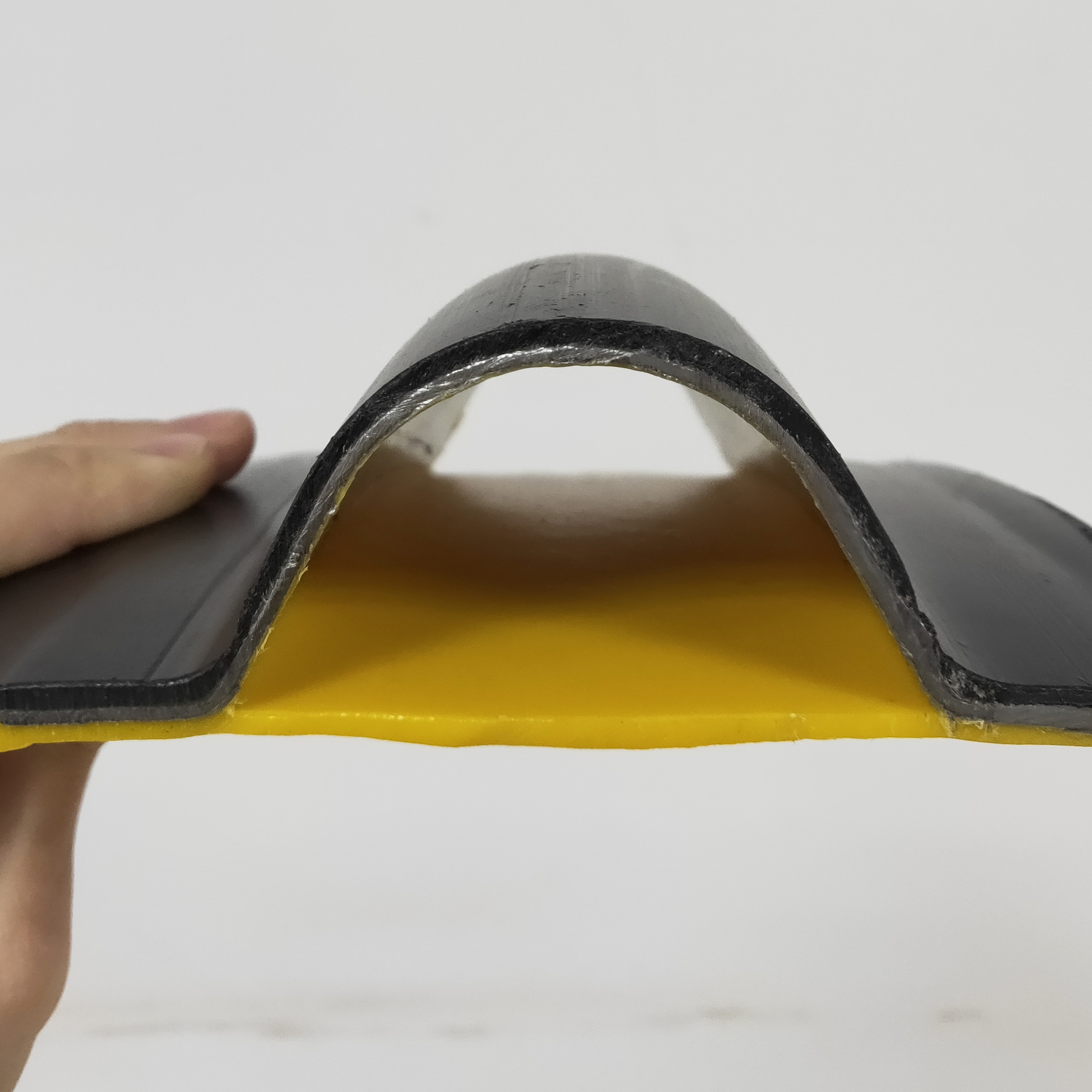

PE steel belt corrugated pipe is mainly for water drainage. Like other kind of plastic drainage pipe, it has the feature of anti-corrosion, good flexibility, low thermal conductivity. In addition, as the pipe also has the steel belt inside. It has much higher ring stiffness, can reach up to SN16, even the lowest ring stiffness is SN8. Our PE steel belt corrugated pipe extrusion line can produce pipe size from minimum ID300mm to maximum ID3000mm. In addition, this pipe has mutual connection method. The most common connection method used in market now is pipe fitting connection. Our company has developed new generation PE steel belt corrugated pipe extrusion line. Compared with old generation, the new generation has following advantage: operation more stable and reliable, line speed increase by more than 30%, power consumption decreased by more than 20%.

Pipe Size (ID, mm) | HDPE Material (kg/m) | Steel Belt (kg/m) | Adhesive Material (kg/m) | Pipe Meter Weight (kg/m) |

300 | 3.5 | 3.8 | 0.6 | 7.9 |

400 | 5.2 | 4.8 | 0.9 | 10.9 |

500 | 7.3 | 7.5 | 1.1 | 15.9 |

600 | 10.5 | 10 | 1.5 | 22 |

700 | 12.6 | 11.8 | 2.3 | 26.7 |

800 | 15.8 | 14.3 | 3.2 | 33.3 |

900 | 18.3 | 17.2 | 3.7 | 39.2 |

1000 | 22.5 | 21.5 | 4.3 | 48.3 |

1200 | 32 | 31 | 5.2 | 68.2 |

1400 | 42 | 40 | 6.0 | 88 |

1600 | 55 | 53 | 7.3 | 115.3 |

1800 | 68 | 65 | 8.8 | 141.8 |

2000 | 78 | 75 | 11.0 | 164 |

2200 | 95 | 85 | 13.8 | 193.8 |

2400 | 122 | 105 | 16.2 | 243.2 |

2600 | 130 | 116 | 21.4 | 267.4 |

2800 | 143 | 128 | 27.3 | 298.3 |

3000 | 172 | 142 | 30.0 | 344 |

Note: all information in the table is for reference only, it varies with different operation process. | ||||