Our company is the earliest manufacturer of PE large diameter hollow wall winding pipe production line in China, and has the national patent of this technology. At the same time, our company also participated in the drafting of the national standard for PE hollow wall winding pipe: GB/T 19472.2-2004.

The PE hollow wall winding pipe production line in the picture produces winding pipe ranging from inner diameter of 1000 mm to 2400 mm. After testing, the machine will be sent to ERA Group. ERA Group has purchased more than 15 PE hollow wall winding pipe production lines from our company. We are honored to provide the production line for ERA Group again.

The raw materials of this test machine are provided by the customer, which better reflects whether the equipment meets the requirements of the customer. For the PE hollow wall winding pipe, since it is a sewage discharge application, the raw material can be used as a new material or a recycled material, but the recycled material must be in quality.

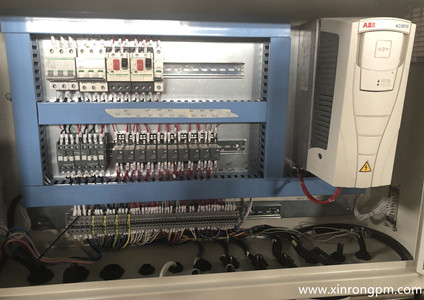

It adopts advanced Siemens touch screen and Siemens PLC control system, which is convenient and stable. The picture shows the operating system of our company’s electrical engineers in debugging the whole line.

The vacuum tank uses SS304 and with sandblasting clean the tank body. Without painting to protect the environment as much as possible.

The vacuum pump in the vacuum tank is controlled by the frequency converter to keep the vacuum within a set range. This way is easy and convenient for operation, also saves manpower and electricity.

Haul off unit is provided to ensure a stable speed when the square tube enters into the winding machine. Haul off unit is equipped with a pressure fine adjustment device to adjust the pressing force to prevent deformation of the square tube. The inlet of the tractor pipe is equipped with an adjusting device to guide square tube to enter into haul off unit.

Pipe with inner diameter from 1000mm to 2400mm can be made on the same winding machine. It is fast and convenient to change pipe sizes. With servo and universal joints inside to make the machine running accurate and stable.

Stacker with motor to move up and down. Supporting roller are driven motor. Distance between supporting roller are adjustable to meet different pipe sizes.