Analysis of Extruder of Plastic Extrusion Machines

Among units in plastic extrusion machine, plastic extruders are often called host machines. Their subsequent devices which used to support plastic extrusion and forming are called auxiliary machines. After 100 years of development of plastic extruders, many models of extruders have been derived from the original single screw extruder. For example, twin screw, multi screw extruders and even extruders without screws. Plastic extruders can work with different auxiliary machines to produce plastic pipe, film, bar, monofilament, flat filament, packing tape, net, plate (sheet), profiles, granulate, coating and other different plastic products. Therefore, plastic extruder is one of the widely used machine in plastic processing industry now and in the future.

By number of screws, plastic extruders can be divided into single screw extruder, twin screw extruder and multi screw extruder. Single screw extruder is currently the most widely used model which can process general materials. Single screw extruder occupies an important position in plastic processing industry and it has been greatly developed in recent years.

Advantages of twin screw extruder are: less heat generated by friction, relatively uniform shear of materials, large convey capacity of screws, stable extrusion, materials are mixed well as they stay a longer time in the barrel.

As twin screw extruder has good feeding characteristics, it is suitable for powder processing. Compared with single screw extruder, it has better mixing, exhaust, reaction and self cleaning function. When processing material and mixed materials with poor thermal stability, twin screw extruder can show its superiority.

On basis of the twin screw extruder, multi screw extruder has been developed in order to process blend materials with poor thermal stability more easily.

Plastic extruders consist of extrusion system, transmission system and heating and cooling system.

- Extrusion system

Extrusion system includes screw, barrel, hopper, die head and mold. Plastics are plasticized into melt evenly by extrusion system. And they are extruded out of die head by the pressure created by the extrusion system.

- Transmission system

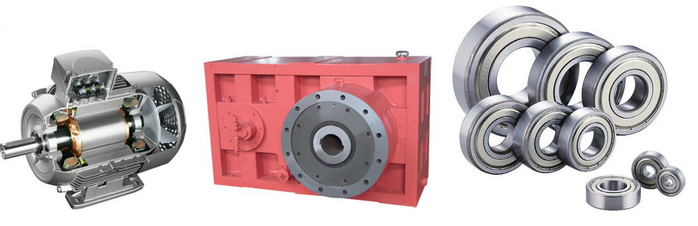

Transmission system is to drive screw, provide sufficient torque and rotating speed to screw. The system contains motor, gear reducer and bearings and others.

- Heating and cooling system

Heating and cooling system is necessary to plasticize plastics and control temperature within the processing temperature of materials.